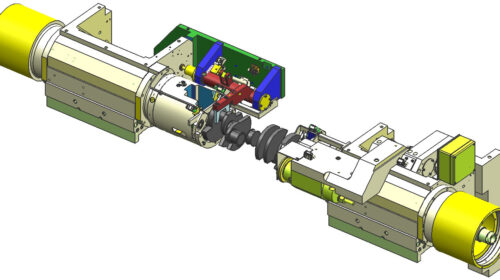

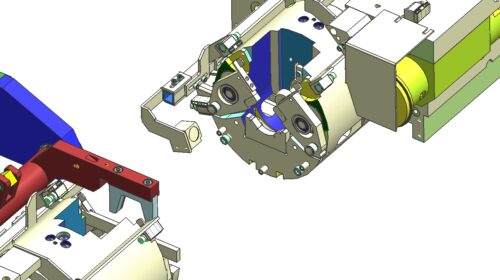

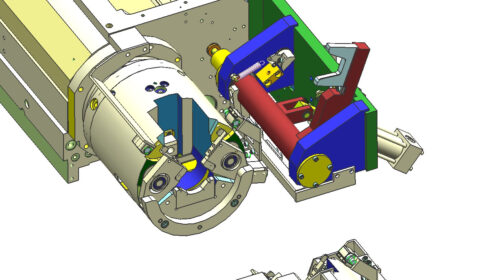

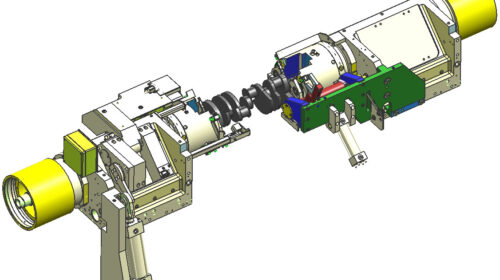

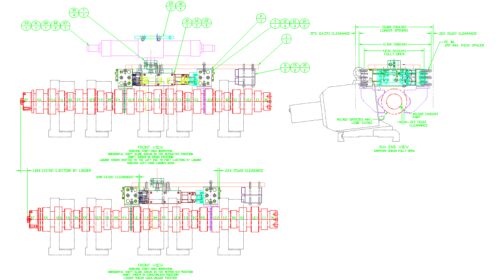

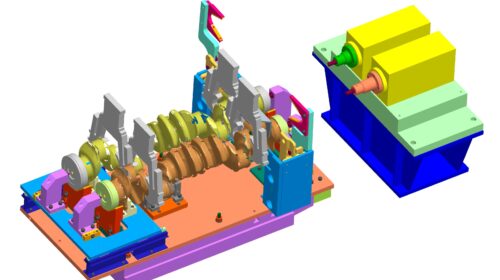

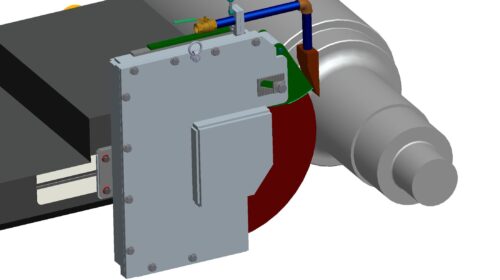

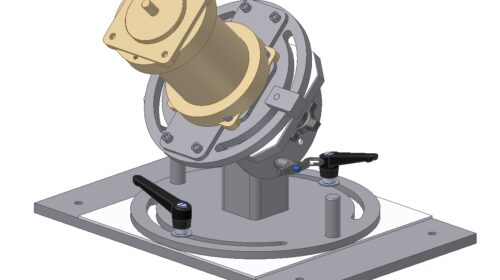

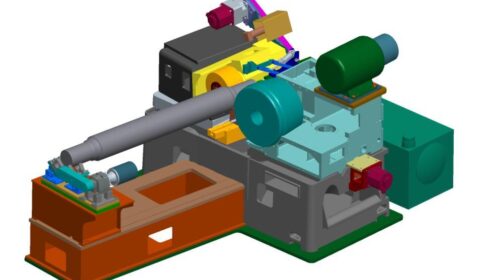

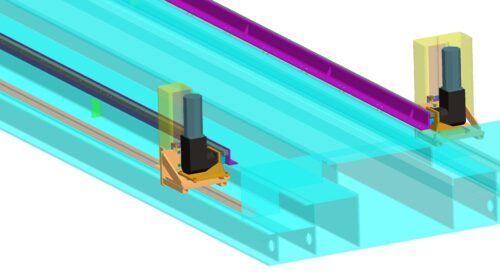

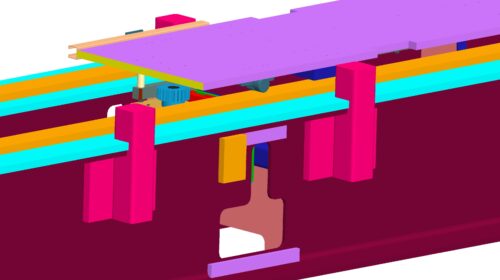

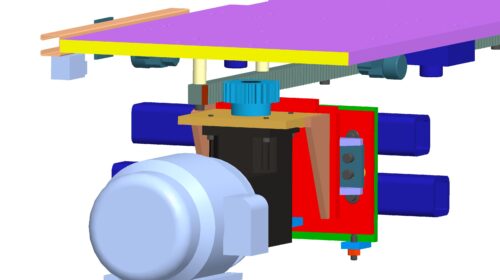

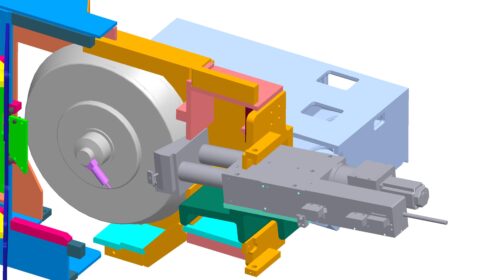

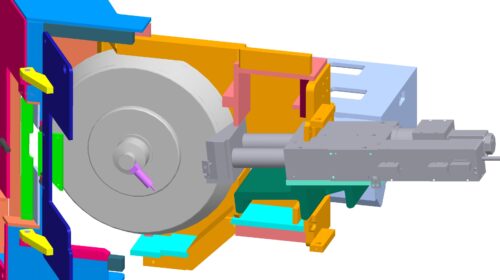

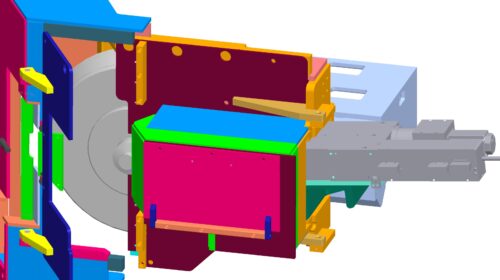

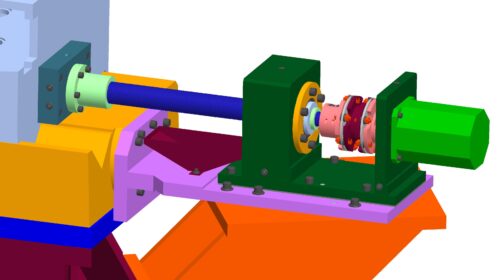

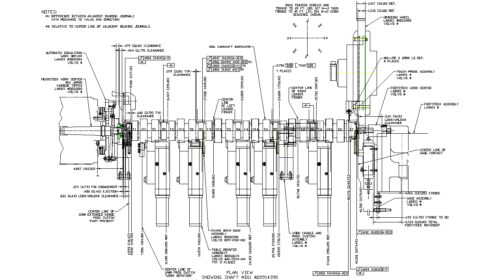

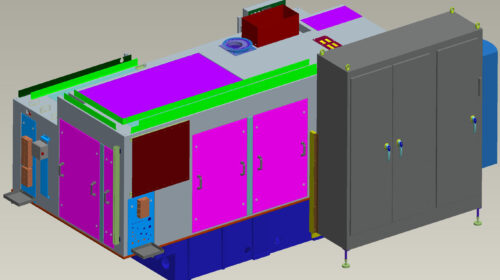

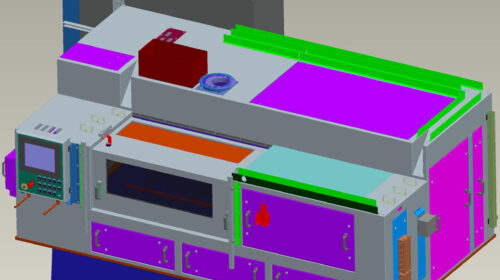

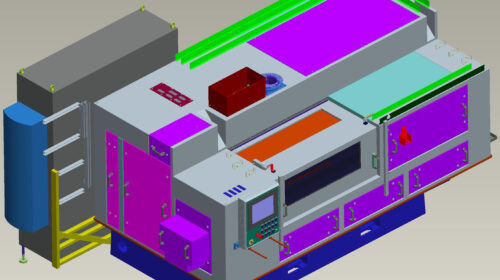

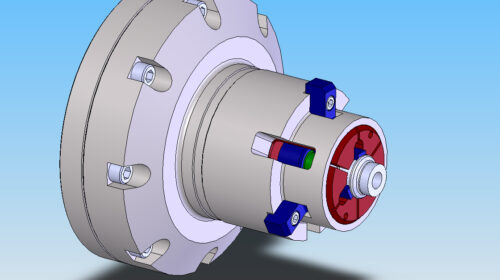

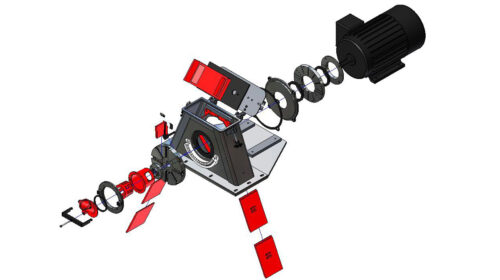

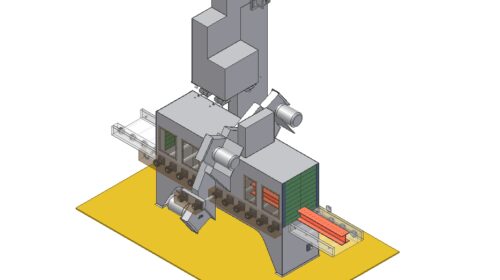

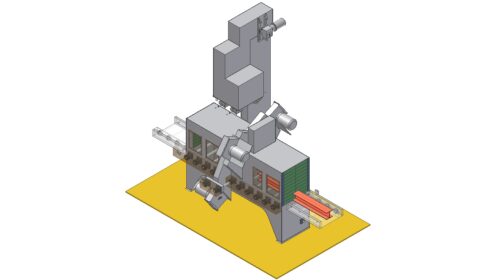

WDSI has been providing the machine tool industry with specialty tooling from our inception. We have worked with grinder OEM's to design/build equipment holding tolerances to the ten thousandths (0.00001) as well as simple holding fixtures for various machining operations. Whatever your need we can provide a solution.