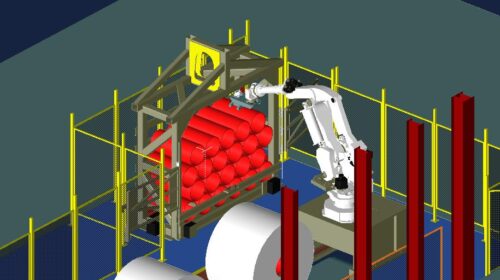

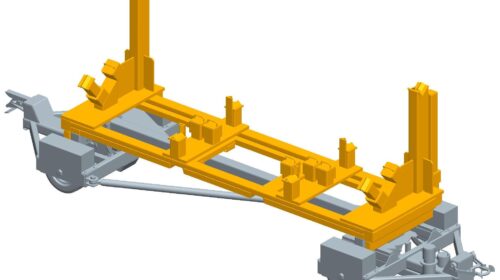

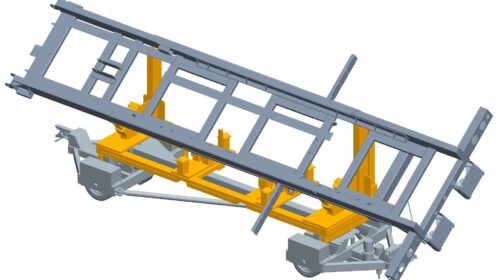

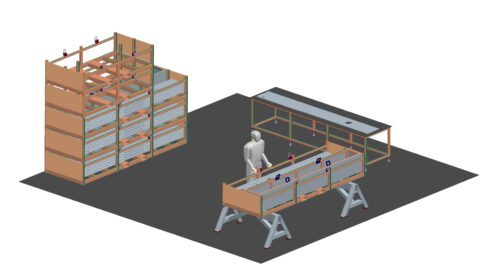

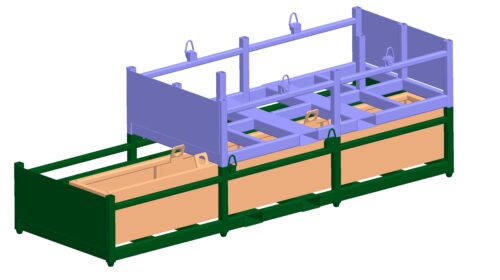

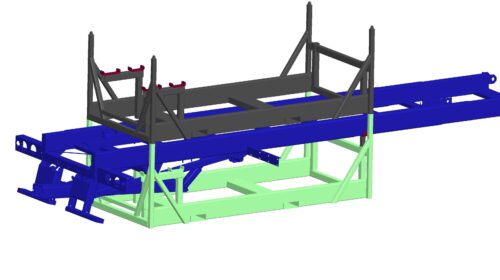

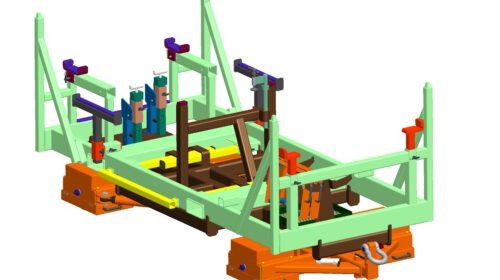

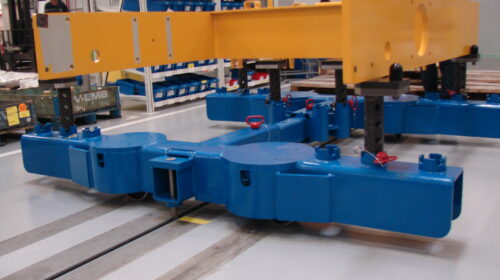

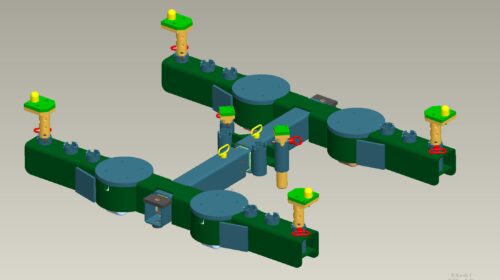

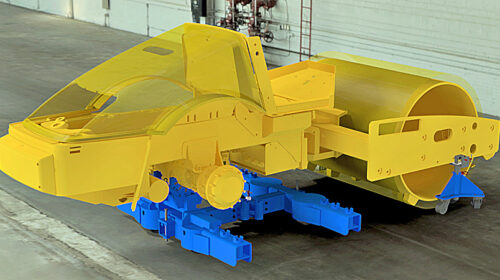

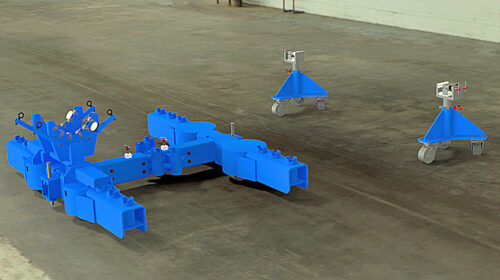

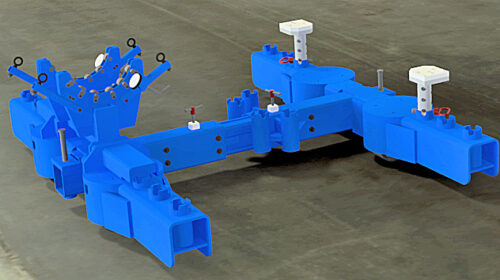

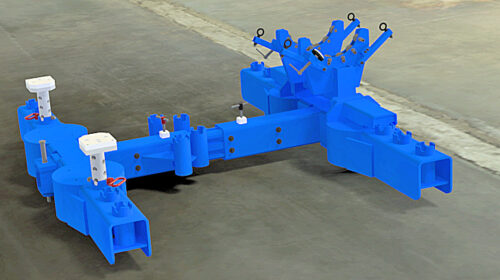

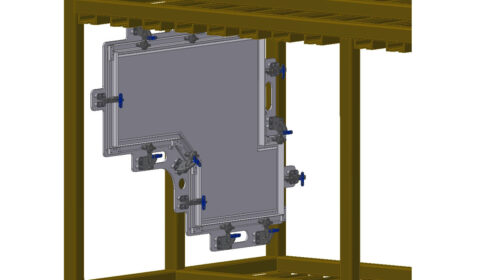

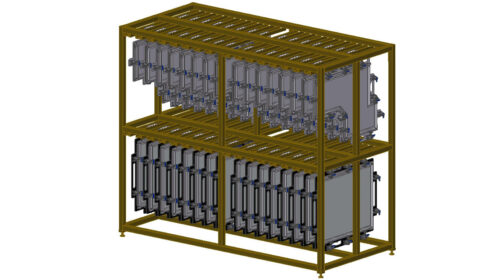

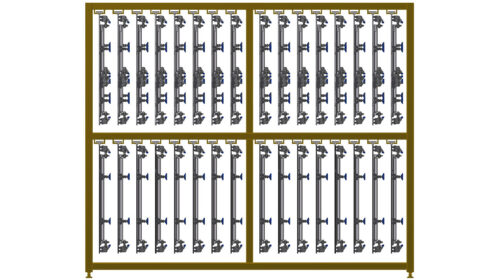

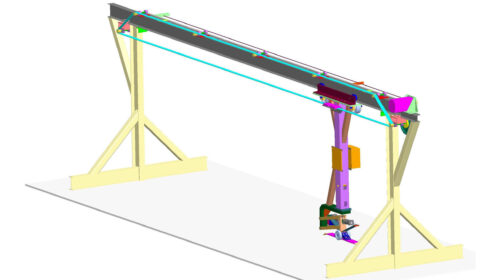

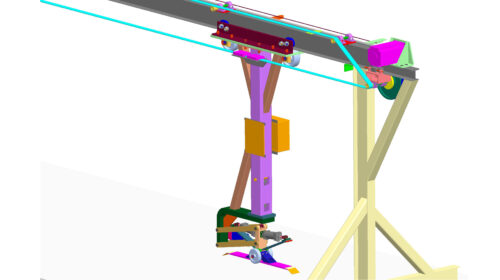

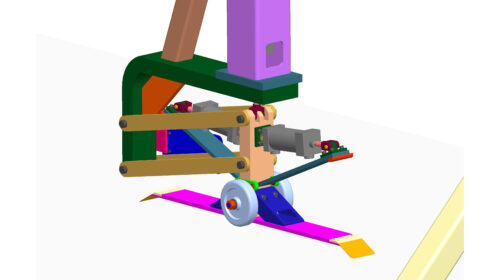

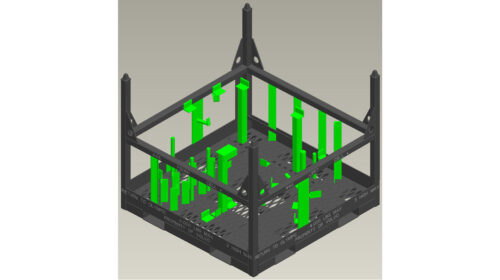

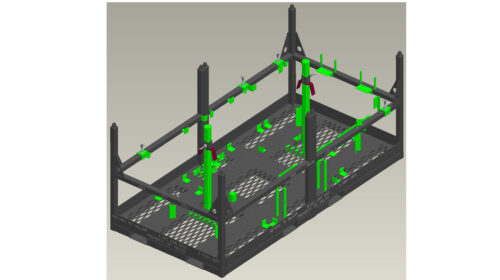

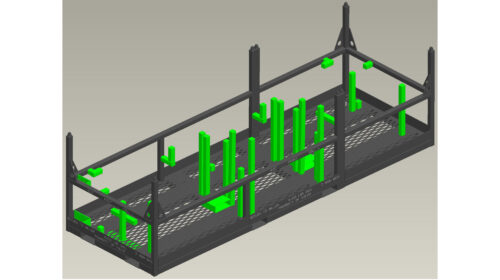

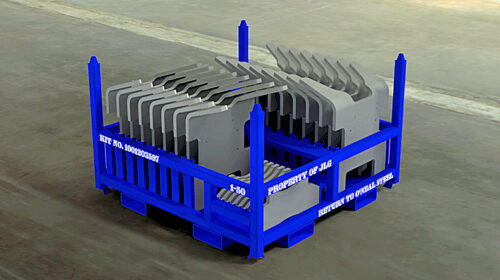

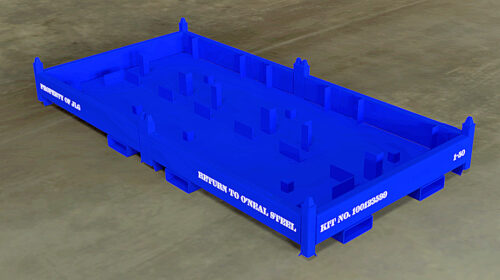

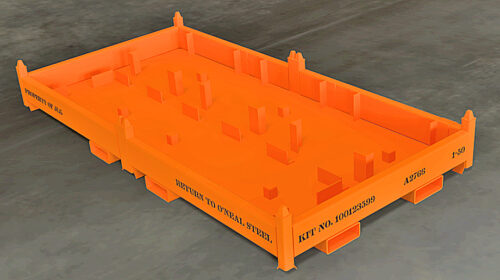

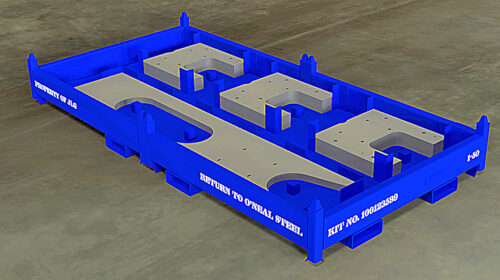

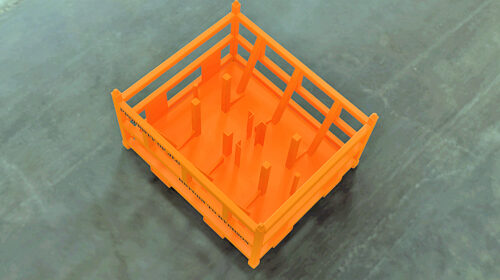

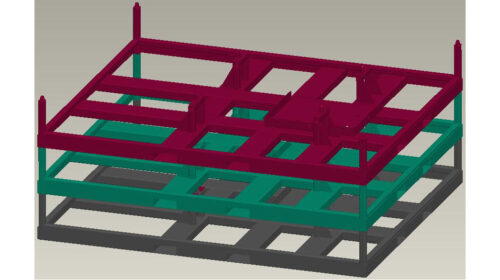

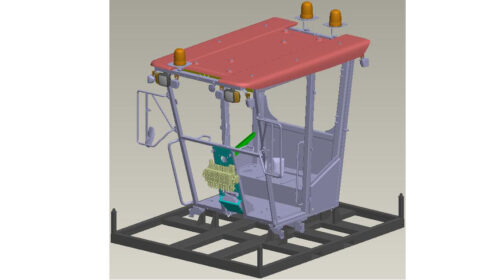

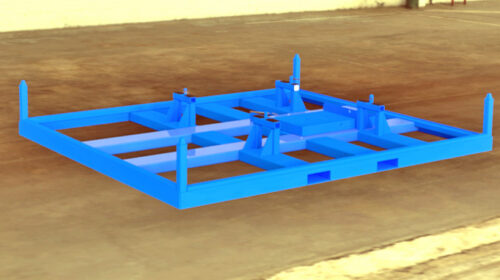

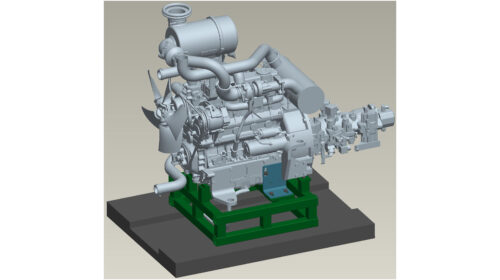

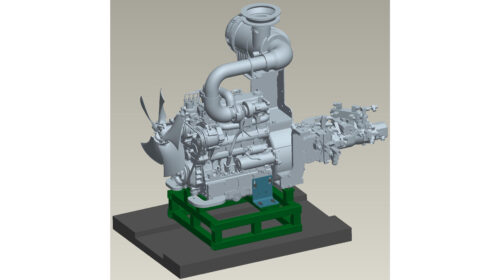

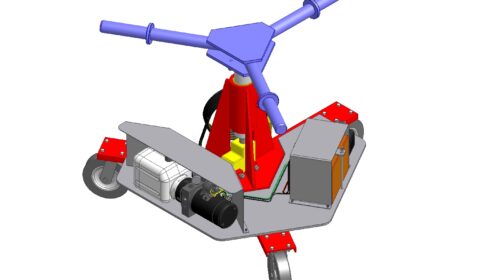

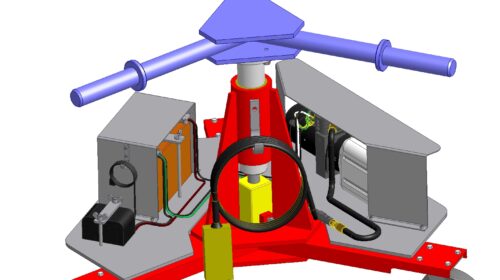

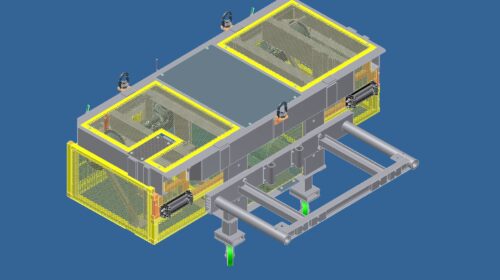

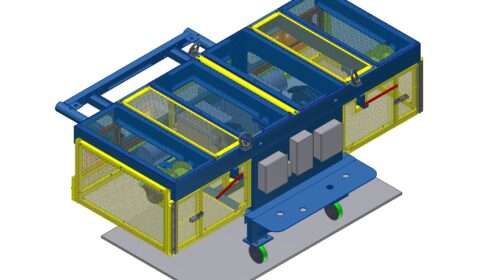

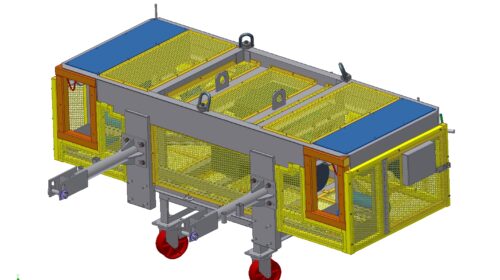

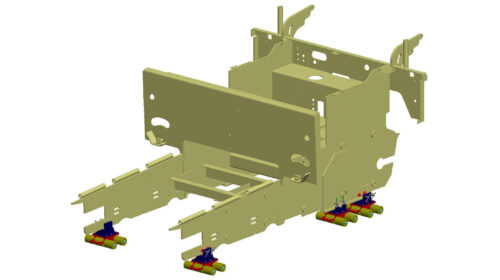

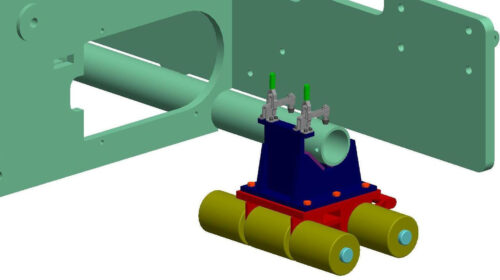

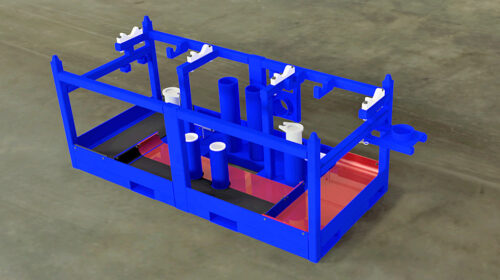

WDSI is your solution for your handling solution. We can provide you with anything from simple conveyor solutions to complex custom design carts to transfer your materials. We specialize in the design/build of the unique one-offs that will create a smooth flow at your facility.